Sneakers are some of the most coveted, collected, and appreciated items in fashion. The hype around them is monumental, so much so that their resale is a whole market on its own, and it’s worth a pretty penny too. Moreover, now that NFTs and digital fashion have joined the party, the industry has been revolutionized, possibly forever. We can confidently say that this development has added several new factors to the market that must be taken into account when playing the game of the hypebeast.

Up until recently, there was a marked difference between a virtual sneaker and a physical one. One could usually tell when a digital sneaker was simply a virtual version of something meant to exist in the physical world, and thus really a physical product on a screen, and when a virtual sneaker was in fact made to exist solely in the digital realm and outside of the physical limitations inherent to the real world. But all in all, it was one thing or the other. Basically, what we’re saying is that the design of a sneaker that was fundamentally meant to exist and function in the physical world would differ significantly from that of a sneaker whose existence was intended to live out in the virtual world.

But it seems to us like there’s a tide coming in, and slowly but surely 3D design, NFT sneakers and digital fashion in general, are distinctly influencing traditional footwear design and manufacturing processes. Now it’s not just life on the streets being migrating to the screens. Now it’s happening the other way round too.

It definitely feels like we are on the brink of a new era of footwear, and we’re here for it. Why you say? Well, because…

3D Printing Technologies allow for more product variation

3D printing sneakers fosters innovation and increases product variation. Think about it, one of the limiting factors of traditional production is the constant gamble on whether a design will sell well or not. In order for production costs to be cost-effective, you have to produce a sizeable amount of pairs of sneakers with the same design. You can’t create a thousand different designs and produce one of each and then hope you’ll sell them all. Your design is, whether you want it or not, influenced by its mass appeal and its ability to sell.

But if the cost for producing a thousand different designs was the same as producing a thousand copies of the same design, brands would be able to produce as many designs as they wish to instead of having no option but to limit their offer to the most palatable model. That’s not to say that it’s a must and every brand should do this, it simply allows for the choice to be there.

Moreover, the timings of the production process would shorten considerably.

We can go further with the design structures thanks to 3D Modeling Technology and 3D Printing

Simply put, additive manufacturing makes it a lot easier and more cost-effective to organically create designs that would be considered unrealistic, outlandish, costly, and time-consuming if produced with a traditional manufacturing process. With a 3D model, designers can let their imagination roam free, becoming a bridge between the physical and digital fashion. By making use of Virtual Reality (VR) and assistive technology in the design process we can take the look and functionality of pairs of shoes further.

This influence of virtual footwear design has transcended the screen and is finally being reflected in the real world. Like a wave approaching the shore that we are only just catching sight of, it’s only a matter of time before this design trend comes crashing down, and floods the market, as trends usually do.

3D Modeling Technology boosts functionality and sustainability

The market has evolved a lot in the last few years, the materials available now are highly advanced compared to traditional raw materials. 3D printed materials can enhance key characteristics of the shoe such as wearability, comfort, and functionality. Midsoles have been produced with 3D technology for quite some time now, as it has proved to be one of the most efficient methods of manufacturing high-performance materials for increased shock absorption, high elasticity, and energy return.

On top of that, materials science has come a long way and has now evolved into a highly sustainable venture. 3D printed products can be made with recycled materials and can employ production methods that do not use any water whatsoever. This makes translates into a highly reduces carbon footprint, as well as the obvious lack of material waste because you literally only print material that is a specific part of the shoe, reducing the waste to zero.

Okay, but who’s making 3D printed sneakers?

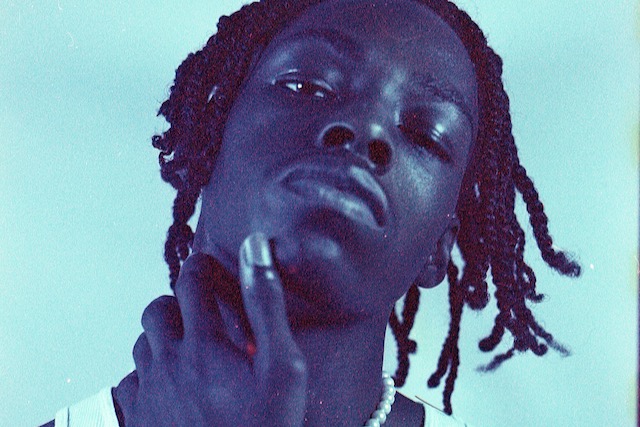

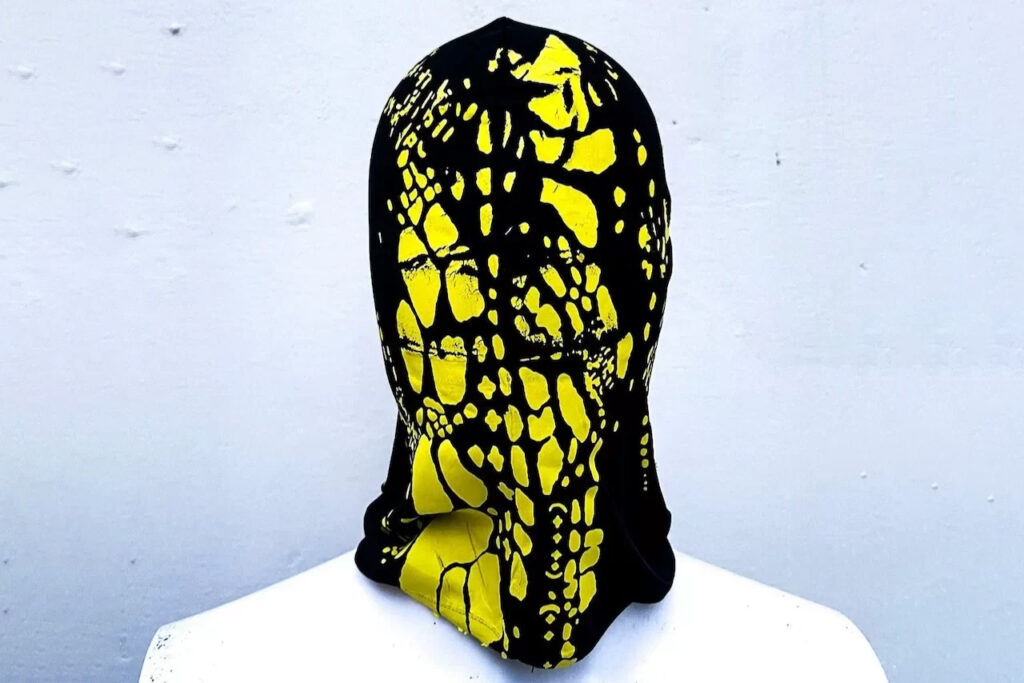

Sneaker design can truly be reinvented, and we can finally begin to see new takes on footwear rather than a redesign of something we’ve seen a million times. Here at TNC we have a few designers we’ve been keeping up with who do not cease to amaze us with every new drop. They are the perfect example of the direction in which this market is headed, they are blazing the trail to the future of sneakers.