3D printed homes are no longer a futuristic fantasy, they are very much a reality. In fact, 3D printed homes might just be the way forward when it comes to cost-efficient and sustainable house building. This year has seen not only 3D homes being built, but projects of entire neighbourhoods being greenlit. We might just be witnessing a turning point for the future of architecture.

How do 3D printing houses work?

3D printing houses consist of using massive 3D printers to, layer by layer, print the structure of the house. Currently, 3D printing houses limit the work that can be done by the printers to the structure of the building. Meaning elements such as windows, electrical, plumbing…etc still have to be installed using traditional construction methods. Nevertheless, efforts to develop a completely integrated printing software with comprehensive mechanical, electrical, and piping components are well underway.

Advantages of 3D printed homes

As of today, a tiny home’s foundation and walls may be printed using 3D printers in under 24 hours for a fraction of the price of a conventional building. We can safely say that by enabling quicker, more affordable, and more sustainable home construction, 3D-printed homes are transforming the construction business.

3D printed homes: The future of sustainable house building

3D printed homes have been hailed as the future of sustainable house building. This green technology produces around 30% of the waste that a typical construction job would. On-demand component printing makes it simple to recycle any leftover materials. Moreover, recycled plastic and other indestructible materials can be used to create the cement mixture that is utilized in 3D printers.

Plus, we can’t forget that 3D printing homes translate into significantly shorter supply chains. Just think of the number of collateral pollution constructions usually generate simply by getting moving the materials around to extract them and get them where they need to be.

3D printed homes are cost-efficient, and therefore accessible

Due to savings in raw materials and, more crucially, labour, 3D printed buildings have substantially cheaper construction costs than traditional techniques. Using 3D printers to accomplish the majority of the building can save the labour expenses associated with an architectural project by up to 80%. By doing away with the necessity for maintaining massive storage facilities and daily transportation of building materials, 3D printed buildings also minimize production costs.

Just so that you can have an idea of the labour costs, the biggest 3D printed building in Dubai took one printer and three workers to make.

At roughly $10,000 on average right now, 3D-printed homes are shockingly affordable to produce. ICON, the pioneer in 3D-printed homes, thinks that these homes will become even more economical in the future, with a projected aim of decreasing construction to $4,000.

The cost-effectiveness of 3D printing housing is one of the major reasons behind 3D neighbourhoods being built in the first place. Such is the case for New Spirit Village, the 3D printed neighbourhood in Oregon, USA being built for the numerous families that lost their homes in the 2020 Alameda Wildfire. 84 affordable, eco-friendly, and fire-resistant homes equipped with solar panels, heat pumps, and a less combustible concrete framework that was 3D printed.

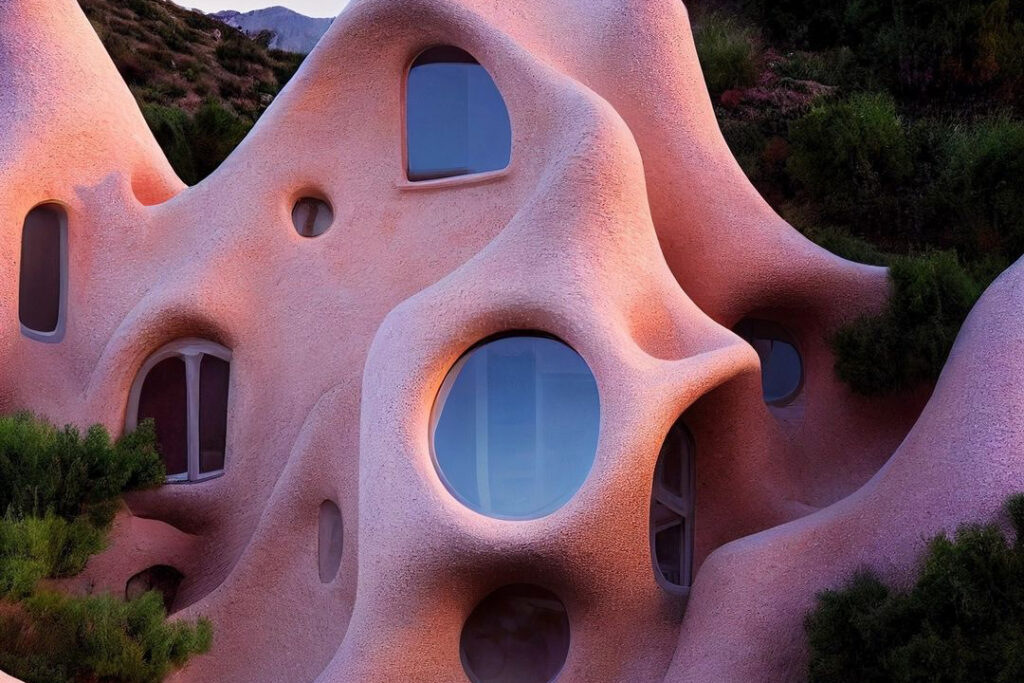

Increased creative freedom

This sustainable technology not only frees up the monetary and sustainability fee one has to invest, but also the creative restrictions that come with traditional home-building techniques. Not just because the material in itself allows for much more flexibility of shape, but because any sort of alteration of the traditional square-shaped house comes with a hefty fee, firstly to find someone who will design it, and secondly to find someone who can physically build it.

However, with 3D technology homebuyers can personalize their home’s shape and build in the blueprint phase without incurring a significant cost.

3D printing will build the homes of the future

… and we don’t mean just figuratively. Dubai has already stated that by 2023, 25% of their homes will be built with the 3D printing method.

ICON, a Texas-based 3D technology business, began the construction on what will become the world’s largest 3D-printed neighbourhood back in November. A few weeks later ICON received a roughly $60 million contract from NASA’s Small Business Innovation Research (SBIR) program, enabling the continuous research of extraterrestrial settings including the Moon and Mars. Translation: They want to build stuff in space using 3D printers.

So if that’s not an indicator that 3D printed homes and sustainable house building are the future of architecture, we don’t know what is.